Range of Hydraulic Valves and Fittings Offered by DURAfilter

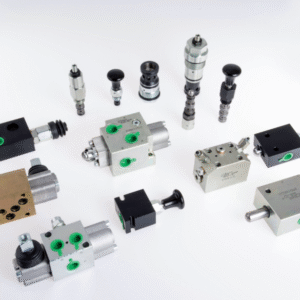

As one of the leading hydraulic valves suppliers, we offer an extensive range of high precision hydraulic valves and fittings designed for durability and efficiency. Our selection includes the following:

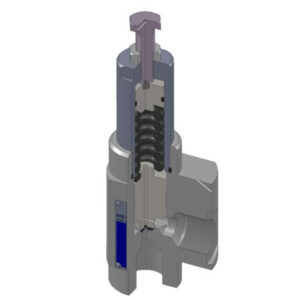

- Safety Valves: These valves provide reliable protection for hydraulic and industrial systems by automatically releasing excess pressure when thresholds are exceeded. Built with high‑quality materials like stainless steel, they offer corrosion resistance, compliance with ASME/API/EN standards, and long‑term, maintenance‑light performance.

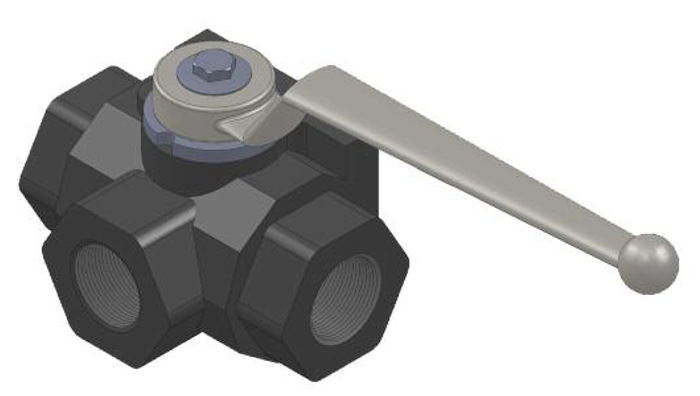

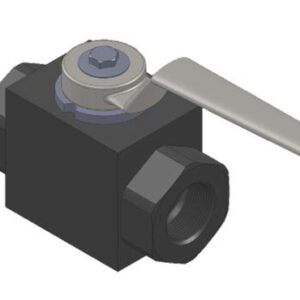

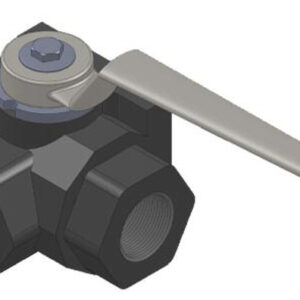

- Shut-off Valves: Shut‑off valves control or stop fluid flow in pressurized systems to prevent damage in high‑pressure environments. They are engineered for long‑term performance, offering reliable pressure isolation, safe maintenance shut‑down, and wide compatibility with hydraulic systems.

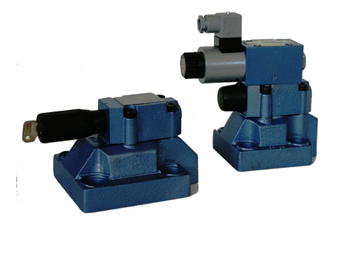

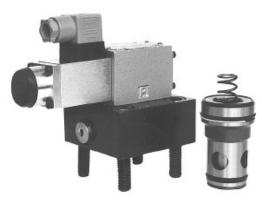

- Relief Valve Blocks: These blocks combine one or more pressure‑relief valves into a compact unit that safeguards hydraulic systems by diverting fluid when preset limits are exceeded.

- Industrial Valves: This category covers various valve types including gate, ball, globe, check and butterfly valves to control, regulate or shut off flow of gases, liquids and slurries in process systems.

Applications Across Industries

DURAfilter’s hydraulic valves are widely used across industries. Some of the key sectors that benefit from our products include:

- Manufacturing and Automation: Hydraulic systems are fundamental in factories and production lines, where precise control and reliability are crucial. Our high pressure hydraulic valves ensure smooth operation and high efficiency in these fast-paced environments.

- Material Handling: In industries like logistics and warehousing, hydraulic systems control lifts, conveyors, and other material-handling equipment. Our valves ensure these systems operate safely and efficiently.

- Construction and Heavy Machinery: Equipment like cranes, excavators, and bulldozers depends on hydraulic systems to function. Our high pressure hydraulic valves are designed to handle the demanding requirements of such machines, providing reliable pressure control and minimizing downtime.

- Marine and Energy: From offshore platforms to ships, hydraulic systems are vital for controlling equipment in the marine and energy sectors. DURAfilter’s offers hyd valve types with the precision and performance needed to handle the extreme conditions found in these industries.

Tips for Choosing the Right Hydraulic Valves for Your Application

Choosing the right types of valves in hydraulic depends on several factors, such as:

- Flow rate requirements: Ensure that you select a valve capable of handling the required fluid flow for your system.

- Pressure ratings: Each hyd valve has a maximum pressure limit. Ensure that the valve you choose can withstand the maximum pressure your system will experience.

- Fluid type: Consider the type of fluid in your hydraulic system (oil, water, etc.) and choose a valve material that is compatible with it.

- Environment: Valves exposed to extreme temperatures or corrosive environments require specialized materials for optimal performance.

If you need help in choosing the right hyd valve types, DURAfilter’s technical support team is available to assist with product selection and provide installation guidance.

Technical Support & Assistance

At DURAfilter, we understand that selecting and maintaining hydraulic valves can be complex. That’s why we offer expert technical support to guide you through the process. Whether you need help with selecting the right product, installing it, or troubleshooting, we are here to help. Our experienced team is always ready to provide solutions that meet your needs, ensuring that your hydraulic systems run smoothly.

Don’t hesitate to reach out for product assistance, request a quote, or explore our full high precision hydraulic valves selection. With DURAfilter’s wide range of high-performance hydraulic valves, we can help ensure your systems are operating at their best.

Frequently Asked Questions (FAQs)

Q. How can I maintain my hydraulic valves?

Ans. Regular inspection and cleaning are important. Check for signs of wear or leakage, and replace seals and parts as necessary to ensure optimal performance.

Q. How long do hydraulic valves last?

Ans. With proper maintenance, hydraulic valves can last for many years. The exact lifespan depends on the system’s operating conditions, including pressure, temperature, and fluid type.

Q. Do you provide custom hydraulic valves?

Ans. Yes, DURAfilter offers custom solutions for specific applications. Contact us to discuss your requirements and get a tailored valve solution.

Q. Are DURAfilter valves compatible with automation systems?

Ans. Yes, our hydraulic valves are designed to integrate seamlessly with automation systems, providing precise control and enhancing the efficiency of automated processes in industries, such as manufacturing and material handling.

Q. How can DURAfilter valves improve safety in industrial applications?

Ans. DURAfilter valves, such as safety and shut-off valves, enhance safety by automatically regulating pressure and fluid flow, thereby preventing system failure, and minimizing the risk of accidents in critical industrial applications.

Q. Can I install DURAfilter hydraulic valves myself, or do I need professional assistance?

Ans. While DURAfilter hydraulic valves can be installed by qualified professionals, we recommend consulting our technical support team for guidance on installation to ensure optimal performance and avoid potential system issues.